Materials: Mild steel wire, Superior quality low carbon steel wire

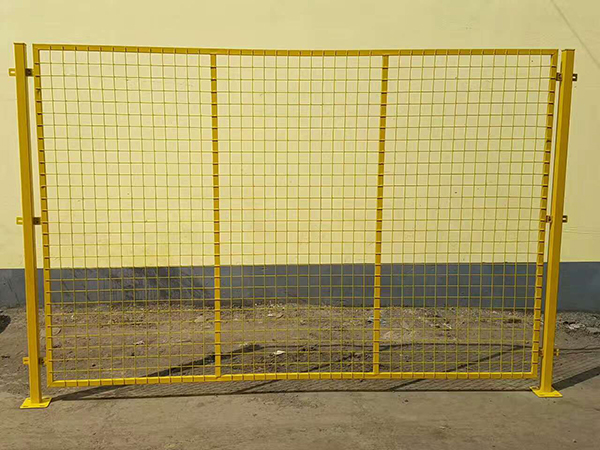

Surface Treatment: Electro galvanizing, hot-dipped galvanizing or PVC coating can be done separately. PVC coated after welding of steel wire.

Process: Drawing wire--- straightening and cutting---welding--- galvanized--- parkerising--- PVC/powder spraying/dipped coating--- packaging

Colors: green(RAL6005), blue, white, red, yellow, black RAL9005, gery etc. as your request

Property: Corrosion resistance, aging resistance, sunshine resistance and weather resistance, easy to transport, easy installed.

Specification:

Panel Height: 1030/1230/1530/1730/1800/1930/2030/2230mm

Panel width: 800/1000/1200/1700/2000/2500/3000/5000mm

Mesh size:

50*200mm 60*150mm

50x50mm 60x60mm 75x75mm(square hole)

80x80mm 50*50mm

Wire diameter: 2.5mm—5.0mm

Support post: diameter 25mm, 32mm, 40mm, 42mm, 48mm

Frame:20*30 20*20 20*40 30*30

Frame thickness: 0.8—2.0mm

Accessories: rainhat, connection card, anti-theft bolt

Advantages of Workshop Separation Fence

They are different from woven wire mesh fences. Due to the line welding processing, it has more firm structure and longer service life compared with woven wire fences.

Hot dipped zinc coated welded wire fence offers thicker zinc plating than electro galvanized one and stronger zinc plating adhesion, while costs a little higher.

PVC coated welded wire fence has more colors available than galvanized welded fences.

The surface treatment of welded wire fence include electro galvanized, hot-dipped galvanized, PVC coated

Usage: Security for construction sites and private property, Security for residential housing sites and schools, For major public events, sports, concerts, festivals, gatherings, Mainly used as isolation fences or safety fences for roads, railway. For traffic control and crowd control.